FACTORY & TECHNOLOGY

Technology

Vapor Heat Treatment system

Vapor Heat Treatment (VHT) is an advanced technology to treat agricultural products with hot steam. Through the sudden change in temperature, VHT helps destroy almost completely all harmful larvae and pests on the outer shell. Without the use of chemicals, the product retains its freshness and nutrients, in addition to ensuring "cleanliness" and extending storage time.

Cold storage system for preservation

Hoang Phat Fruit is equipped with a state-of-the-art cold storage system with the ability to meet a suitable temperature and humidity range for each type of fruits, combined with a 24/7 monitoring and control system and periodic inspection staff to ensure:

- Preservation of large amount of products

- Nutritional quality and helps prolong storage timeProduction process

_crop_HIEU5271.jpg)

_crop_HIEU4986.jpg)

_crop__MG_1049.jpg)

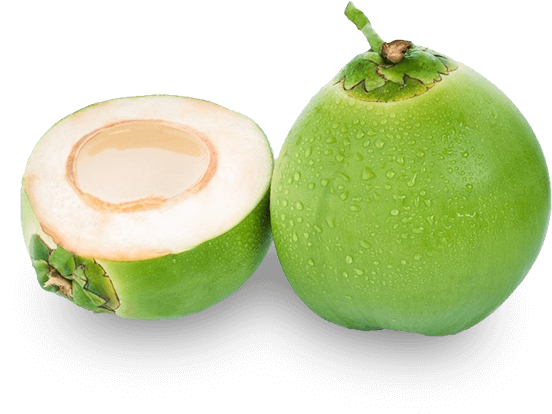

HP Farm's raw material area always meets VietGAP, GlobalGAP & IS0 9001 standards

_crop__BOO3006.jpg)

_crop_HIEU5441.jpg)

_crop_Screen_Shot_2022_10_19_at_24635_PM.png)

_crop__MG_1101.jpg)

_crop_HIEU5680.jpg)

After the fruits are transported to the factory, preliminary processing will be carried out based on the regulations of each market and according to the standards of Hoang Phat Fruit.

Sorting (by size)

Removing unqualified fruits: insect-infested, bruised, bad shaped…etc

Cutting off fruit stalks and cleaning

_crop__BOO3312.jpg)

_crop__BOO3168.jpg)

_crop__BOO3111_1.jpg)

Products are put into the vapor heat treatment machines. At the same time, the inspection experts will operate the process and monitor through high-tech sensors

_crop_8_lam_mat_bang_nuoc_.jpg)

_crop__BOO3345.jpg)

The products are then put into cooling storage and continue to cool down.

_crop_HIEU5866.jpg)

_crop__BOO3333.jpg)

_crop__LUX8234.jpg)

_crop_HIEU5936.jpg)

_crop__LUX7782.jpg)

_crop__BOO3288.jpg)

1. Products are cleaned and passed through the last quality controlled inspection round

2. Products are then labeled

3. Products are weighted before packaging

4. Package the products with quarantine and quality control stamps (according to each market requirements)

_crop__LUX7866.jpg)

_crop__LUX7858.jpg)

Product are organized onto pallets; and moved to cool storage warehouse

_crop_z4316699727662_b7c5714768dd3271bd6da50e60023969.jpg)

_crop_z4316699703726_898e794bad703c0a231bbe6c40641b10.jpg)

_crop_Screen_Shot_2022_10_19_at_31133_PM.png)

Factory experts will take one last final, random sample test of the products and sign the quarantine certificate before shipment

_crop__BOO3462.jpg)

Certifications

Product quality and food safety are always the company's top priorities.

Hoang Phat Fruit strictly controls, at every single step, the processes from the initial stage until the product reaches the consumer.

Our internationally recognized certifications: Hazard Analysis Critical Control Point (HACCP), GLOBAL G.A.P, Sedex SMETA, ISO: 9001

_crop_he_thong_xu_ly_nhiet.jpg)

_crop_chuoi_kho_lanh.jpg)

_crop_nha_may_hoang_phat_fruit_2.jpg)

_crop_nha_may_hoang_phat_fruit_6.jpg)

_crop_nha_may_hoang_phat_fruit_1.jpg)

_crop_nha_may_hoang_phat_fruit_4.jpg)

_crop__BOO3111.jpg)

_crop_6_dua_vao_may_chuan_bi_xu_li_VHT.jpg)

_crop__LUX7849.jpg)

_crop__LUX8489.jpg)

_crop__BOO3126_2.jpg)

_crop_Screen_Shot_2022_10_19_at_24635_PM.png)